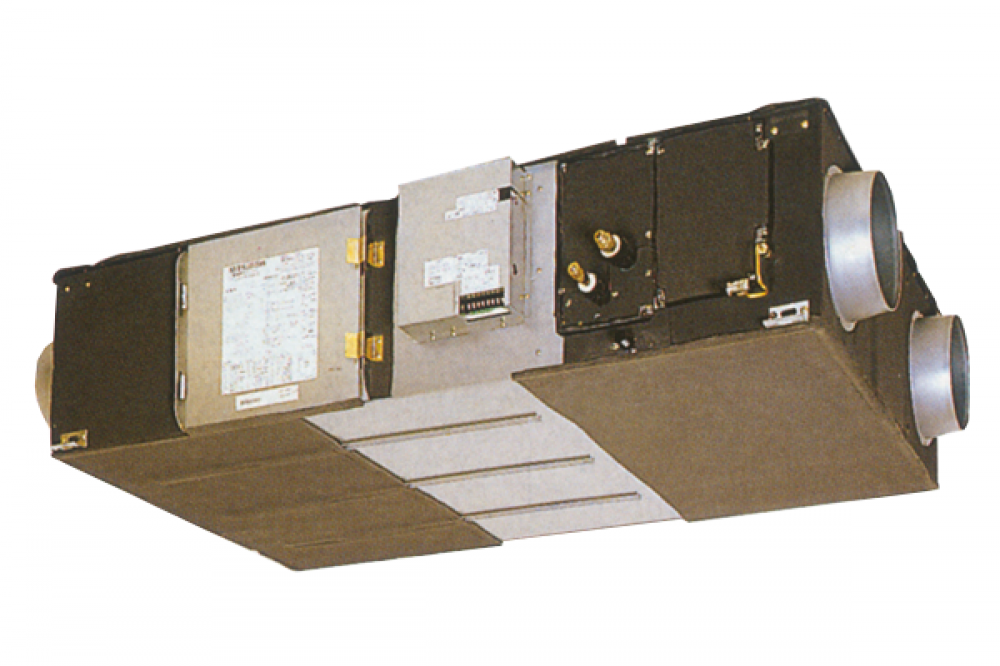

GUF

Monoblock indoor unit with fresh air intake fan, stale air exhaust fan, filtration system, Lossnay total heat recovery module, bypass shutter, permeable film humidifier (only for RDH4 version) and direct expansion coil.

Cooling capacity 5.57 (DX coil: 3.63, Lossnay core: 1.94) kW

Heating capacity 6.18 (DX coil: 6.21, Lossnay core: 2.04) kW 500 m³/h 220-240V 50Hz single-phase GUF-100RD(H)4.

Cooling capacity 11.44 (DX coil: 3.63, Lossnay core: 3.85) kW

Heating capacity 12.56 (DX coil: 8.30, Lossnay core: 4.26) kW 500 m³/h 220-240V 50Hz single-phase

Lossnay technology

The Lossnay total heat recovery module has a cross-flow plate fin structure and heat transfer diaphragms in special treated paper. The excellent thermal transfer properties and permeability to moisture of this special paper ensure the highly efficient exchange of both sensible and latent heat between the two air flows passing through the recovery core. The result is a ventilation system with outstanding characteristics ensuring extremely

high levels of comfort and wellbeing in the environment treated, which can also cut operating costs substantially. The incoming fresh air and outgoing stale air cannot mix within the core.

The diaphragm pores, which were already microscopic in previous generations, have been further reduced in size to reduce the possibility of thepassage of waterborne soluble gases such as ammonia and hydrogen. To

increase heat and moisture exchange, a special treatment is applied to the paper used for the diaphragms. These improvements have increased moisture permeability while reducing permeability to harmful gases, resulting in an overall increase in recovery efficiency and a more effective barrier action against the transfer of these gases.

Heat exchanger

A direct expansion coil incorporated in the unit makes it possible to cover approximately 25% of the load of the system with the GUF unit. This also means that the terminal units installed in the indoor space can be smaller. Moreover, as the GUF unit covers the entire thermal load attributable to ventilation, this means that this load and the ambient load can be managed completely separately, simplifying the design process of the installation. The treated air heats the humidifier as it passes through it, further increasing humidification efficiency

Total comfort

Maintaining the correct humidity levels in an indoor space ensures the ideal conditions for comfort and prevents the unpleasant side-effects typical of an environment with insufficient humidity such as dry eyes and throat.

The evaporation surface area is approximately 8.5 times larger than in a comparably sized natural evaporation humidifier, while performance is 6 times greater.

Increased efficiency of humidification process - RDH4 version

Optimised air flows within the unit together with a water injection system have significantly increased the efficiency of the humidification process. The system also controls the humidity in the outgoing stale air to effectively improve the air quality of the outdoor environment as well. This solution prevents limescale and silica dust from being carried in the air, so purer, less dusty air is vented into the outdoor environment.

Advantages

• Reduced energy consumption

• Reduced thermal power necessary to treat outdoor air, equating to lower

rated power

• Healthier environment

• Quieter operation (noise baffles in inlet and outlet)

• Free Cooling function using exclusively external air

• Humidification with film permeable to water vapour only

• Total air treatment (neutral air returned to outdoor environment)

• Custom temperature and humidity control

• Compact dimensions

• Installable in double ceilings with limited vertical space.